Starting a Merch Brand in 2025: The Practical Playbook for Creatives

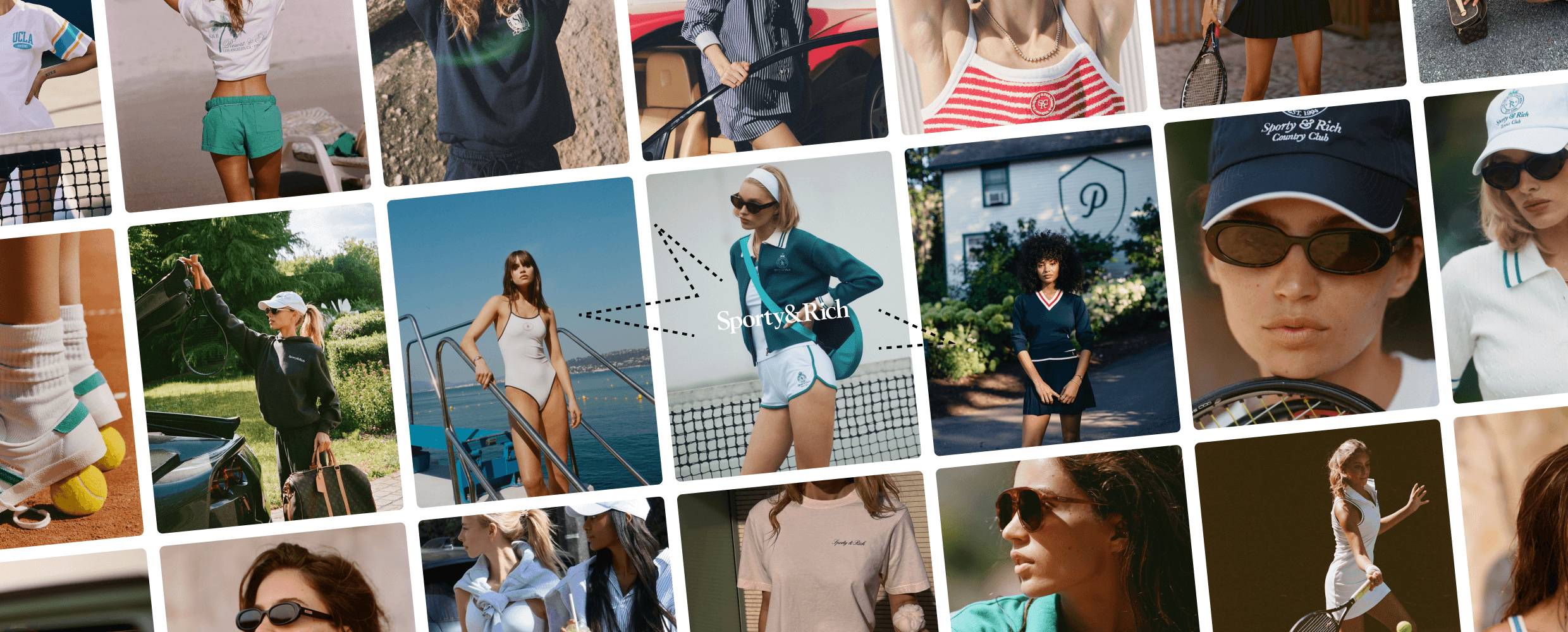

Merch has entered its design era. Today’s drops build loyalty, tell stories and turn audiences into communities. What used to be an afterthought is now a design-led channel that blends fashion, storytelling, and strategy.

At Fabra, we believe modern merch deserves modern tools - fast, collaborative and creative - so you can focus on design, not production headaches. This playbook shows how to turn an idea into a tangible brand moment, from concept to first drop, using the same principles behind today’s most intentional merch lines.

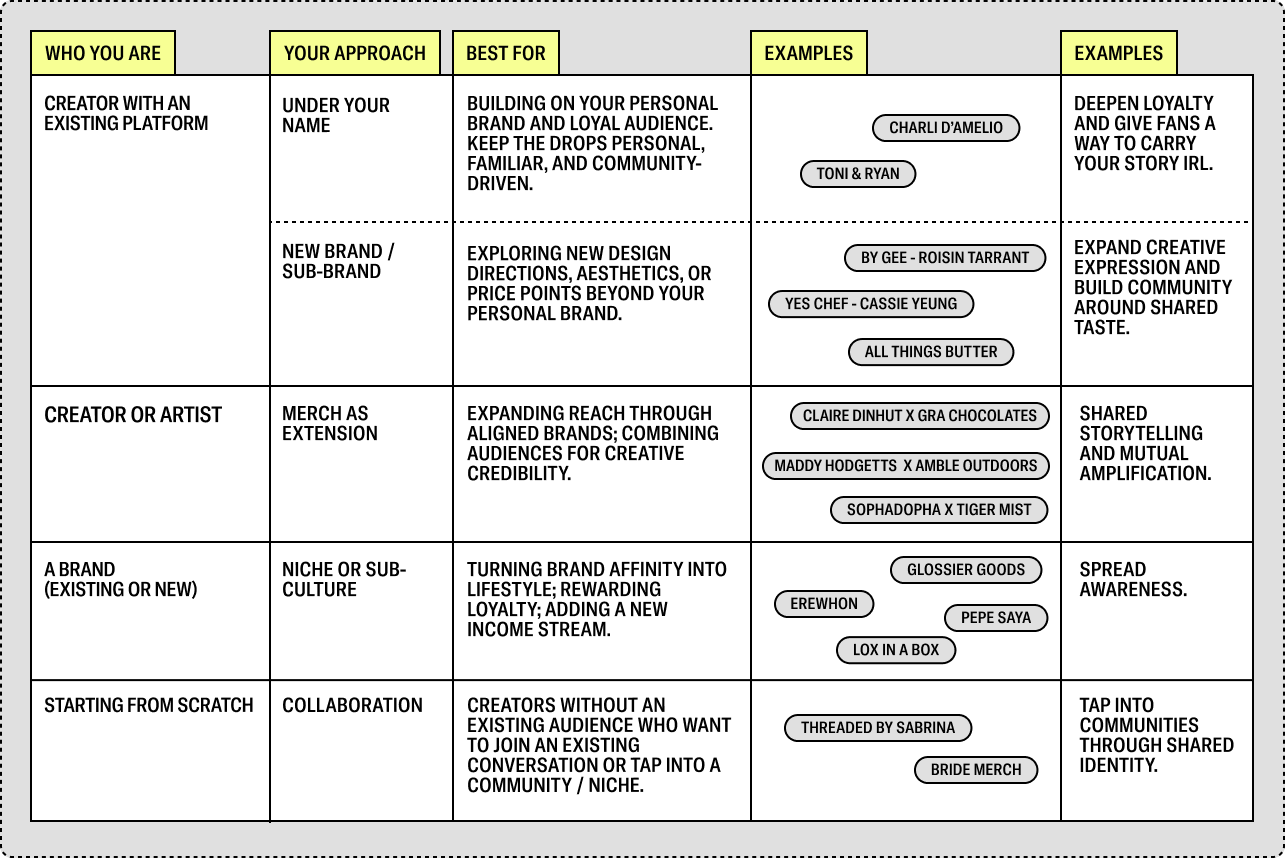

Step 1: Brand & Purpose

Before you design anything, get clear on who you are and who you’re creating for.

1.1 Define your goal (Why)

Are you optimizing for awareness (get your brand into more hands), community (give fans a wearable signal), or revenue (a new income stream/test for a pivot)? Pick one and let it steer price, materials, and launch plan.

Ask yourself:

- Is this drop about building awareness: getting your brand into more hands and conversations?

- Is it about deepening community: creating something for fans, listeners, or customers to wear with pride?

- Or is it a commercial play: a new income stream or test case for a larger brand pivot?

There’s no wrong answer, but there should be a clear one.

Examples:

- Awareness: Lox in a Box turns customers into walking billboards with its signature green merch - designed to spread brand visibility beyond the store.

- Community: Tony & Ryan use their podcast merch to turn inside jokes into shared identity, strengthening loyalty and fan connection.

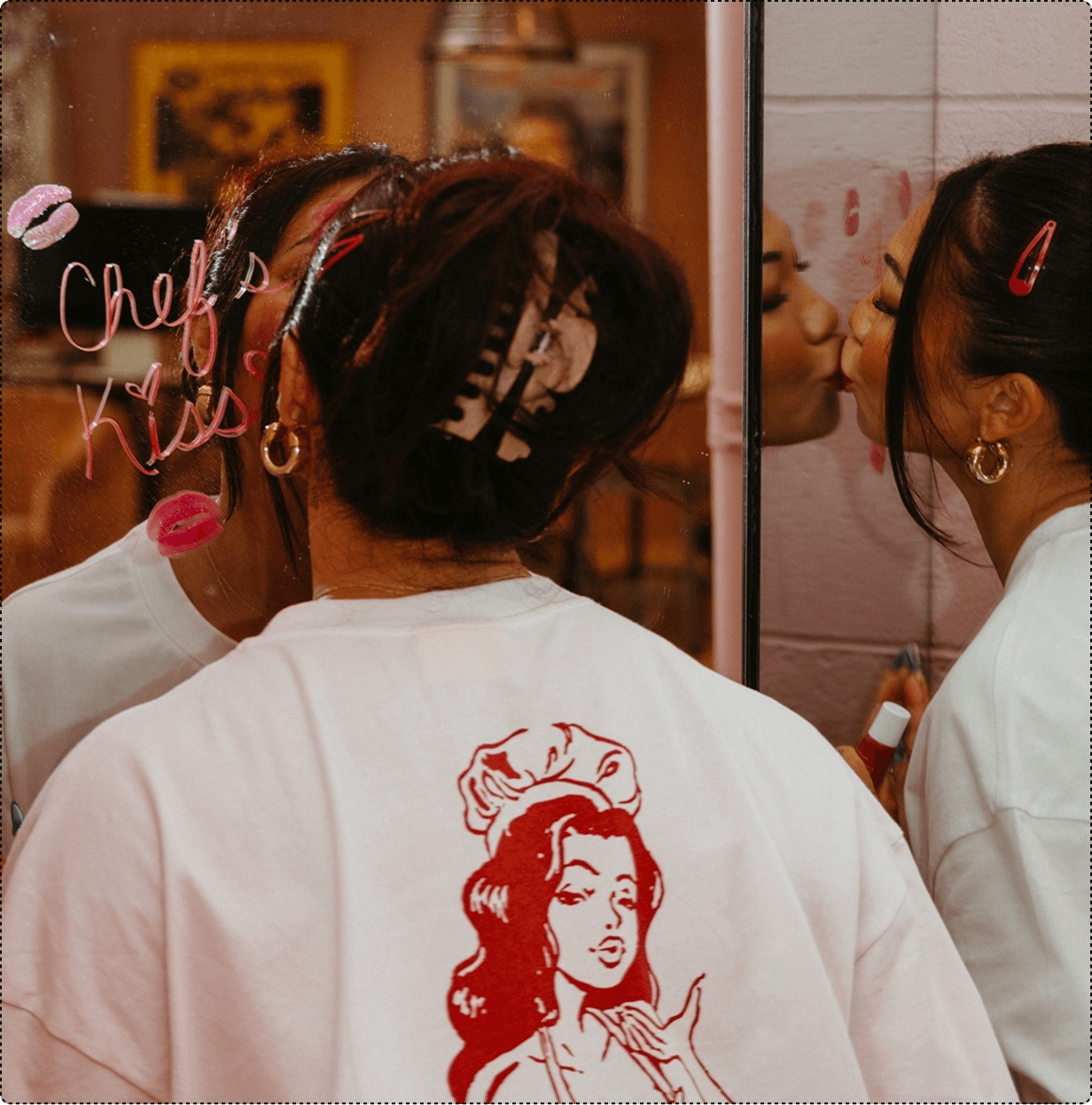

- Commercial: Cassie Yeung’s Yes Chef range evolved from a viral series into a high-performing lifestyle sub-brand - merch that became its own business.

1.2 Define your Audience (Who)

- If you have an existing community: Co-create. Run quick polls (cropped vs classic? hoodie vs crew? $60 vs $80), scan comments/DMs and check your demographics.

- Starting fresh: Do a competitor scan (8-12 adjacent brands), spot best-sellers vs shelf-sitters, read reviews/forums to find the gaps (fit, fabric, price).

1.3 Refine your Brand

A clear visual direction keeps your merch cohesive and gives every drop a through line:

- Core palette (+ secondary accents)

- Typography (primary + support)

- Logo variations (print/embroidery/small scale)

- Illustrations, graphics or icons

- Catchphrases and taglines

- Mood boards and photo references

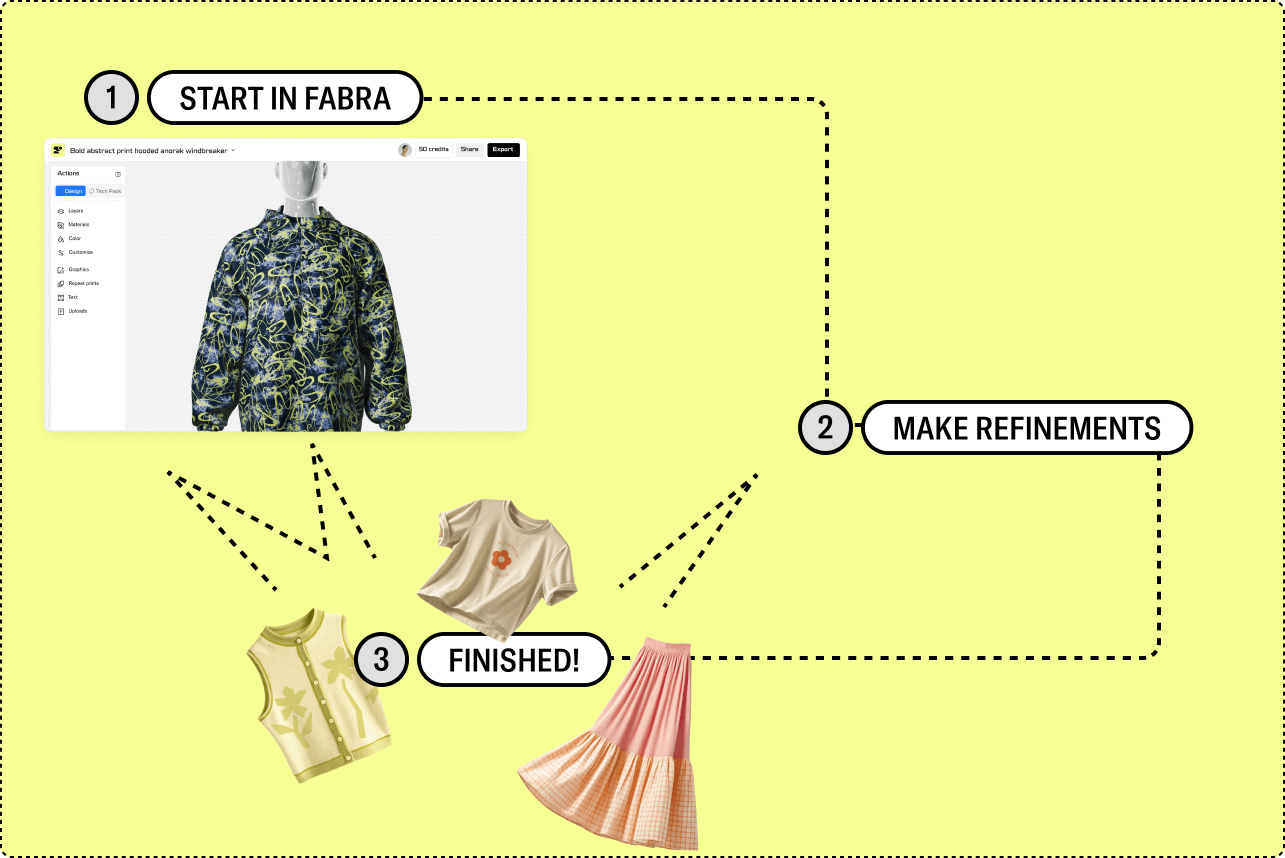

Step 2: Design Your Drop

This is where your concept becomes visual - and where Fabra does the heavy lifting. With Fabra, you’ll be able to experiment with silhouettes, colors, graphics and placements at the click of a button - and see your product come to life before it ever hits production.

2.1 Moodboard & Direction

Start by collecting references; color palettes, typography, graphics, images and silhouettes. Pinterest, old campaign imagery or your brand’s own visuals are all fair game. Keep your audience segment in mind - you’re not designing for everyone, just your audience.

2.2 Design Elements

When you move from inspiration to execution, focus on the details that make your brand distinct:

- Silhouettes: Tees, crews, hoodies, caps, totes - choose shapes that suit your audience’s lifestyle.

- Graphics & placement: Play with graphics, patterns and placements to create a design that’s on-brand.

- Fabric & color: Align with your brand palette. Fabra’s full Pantone palettes let you experiment freely before you commit.

- Messaging: Keep it short, recognizable, and true to your tone.

Step 3: Make your Garment Pattern

Before you create your tech pack, you need a garment pattern; the blueprint for how your design is actually constructed. A pattern outlines the exact shapes, curves and measurements for every piece of fabric that will be cut and sewn together.

It’s the architectural plan of your product.

Why it matters:

- Ensures accurate and consistent fit.

- Reduces fabric waste and cutting errors.

- Forms the foundation of your tech pack.

- Speeds up sampling and reduces revisions.

How to Create One

- In Fabra: Once your design is finalized in 3D, Fabra can generate pattern-ready specifications that align perfectly with your tech pack - reducing errors and saving weeks of back-and-forth.

- With a pattern maker: If you prefer a manual approach, a freelance pattern maker or your chosen manufacturer can turn your design into a digital pattern.

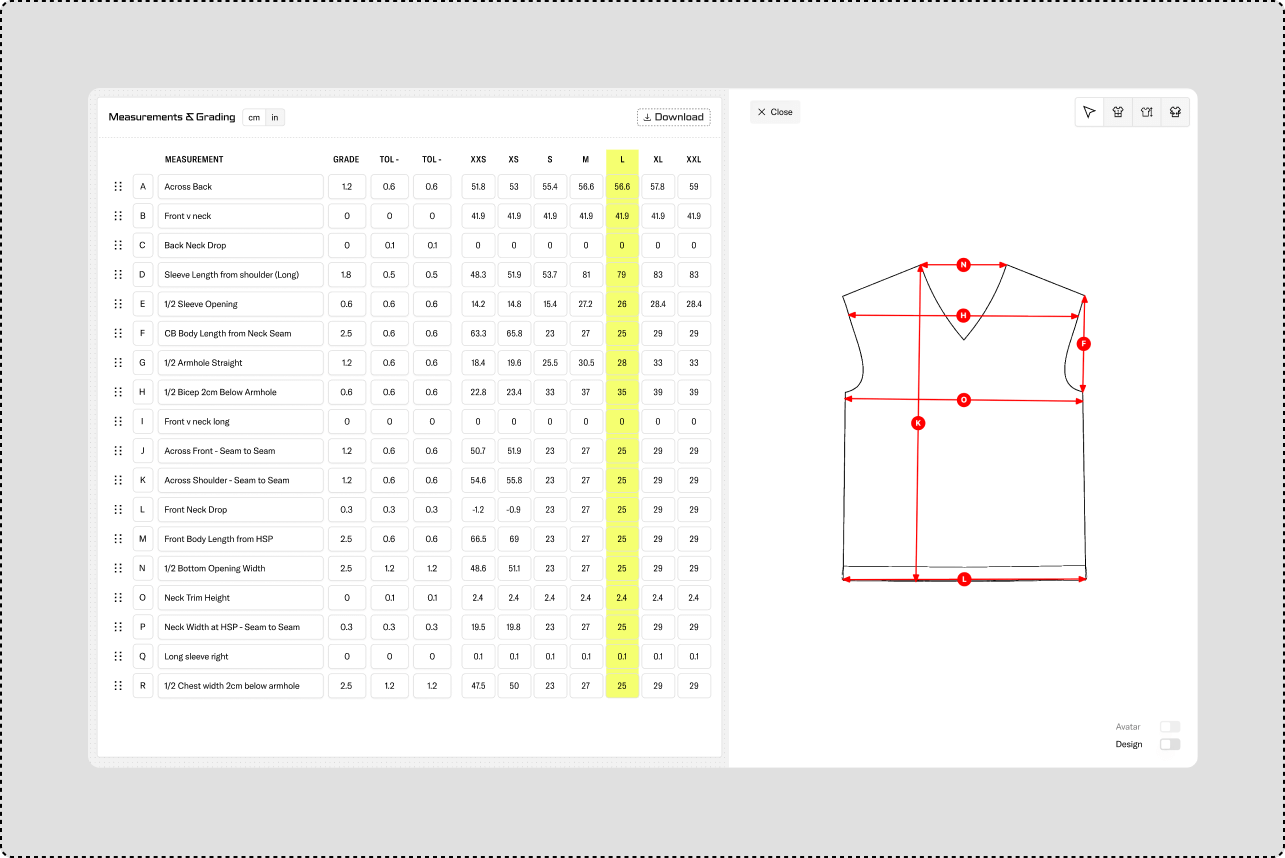

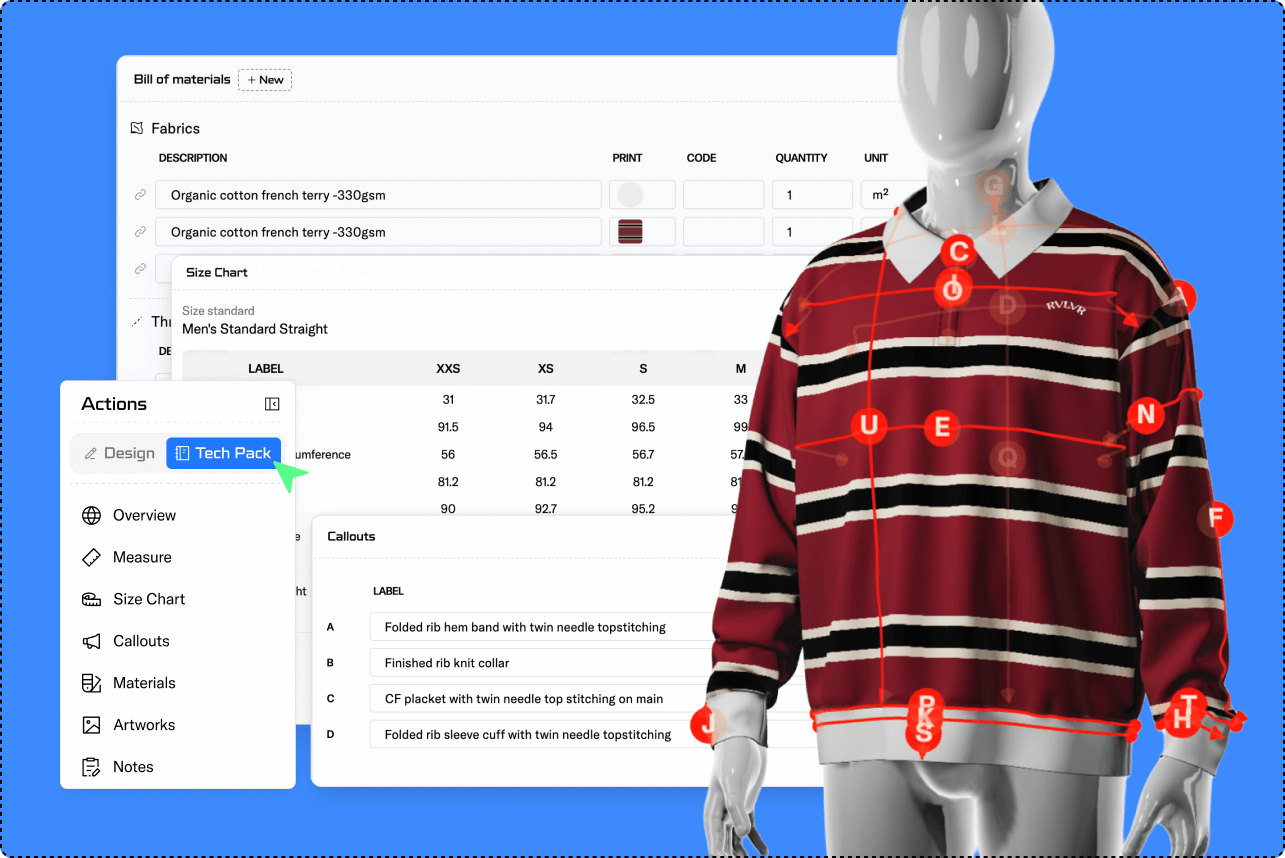

Step 4: Build a Tech Pack (Non-Negotiable)

Your tech pack is the blueprint your manufacturer will follow - the single most important document in your entire production process with a full set of instructions to bring your product to life.

Once your garment pattern is ready, your tech pack pulls everything together so your manufacturer has zero guesswork.

What to include:

- Flat sketches (front/back)

- Measurements (by size)

- Fabric & color (material, weight, Pantone/dye codes)

- Pattern/print/embroidery (placement, scale, finishes)

- Labels & trims (care/brand/swing tags; buttons/zips)

- Construction notes (stitch, hems, special details)

A great tech pack:

- Speeds up communication with your manufacturer.

- Reduces sampling errors and costly revisions.

- Keeps quality consistent across factories and future production runs.

This is why it’s non-negotiable. Without it, your manufacturer is guessing.

How to Create One

- In Fabra: Design your garment in 3D and generate an export-ready tech pack instantly. Your measurements, colors, graphics, placements and pattern details all flow directly from your design - saving weeks of manual work.

- With a freelancer: A good option if you need complex or custom patterning, but make sure to budget time and cost for revision rounds. Every sample change requires a new tech pack.

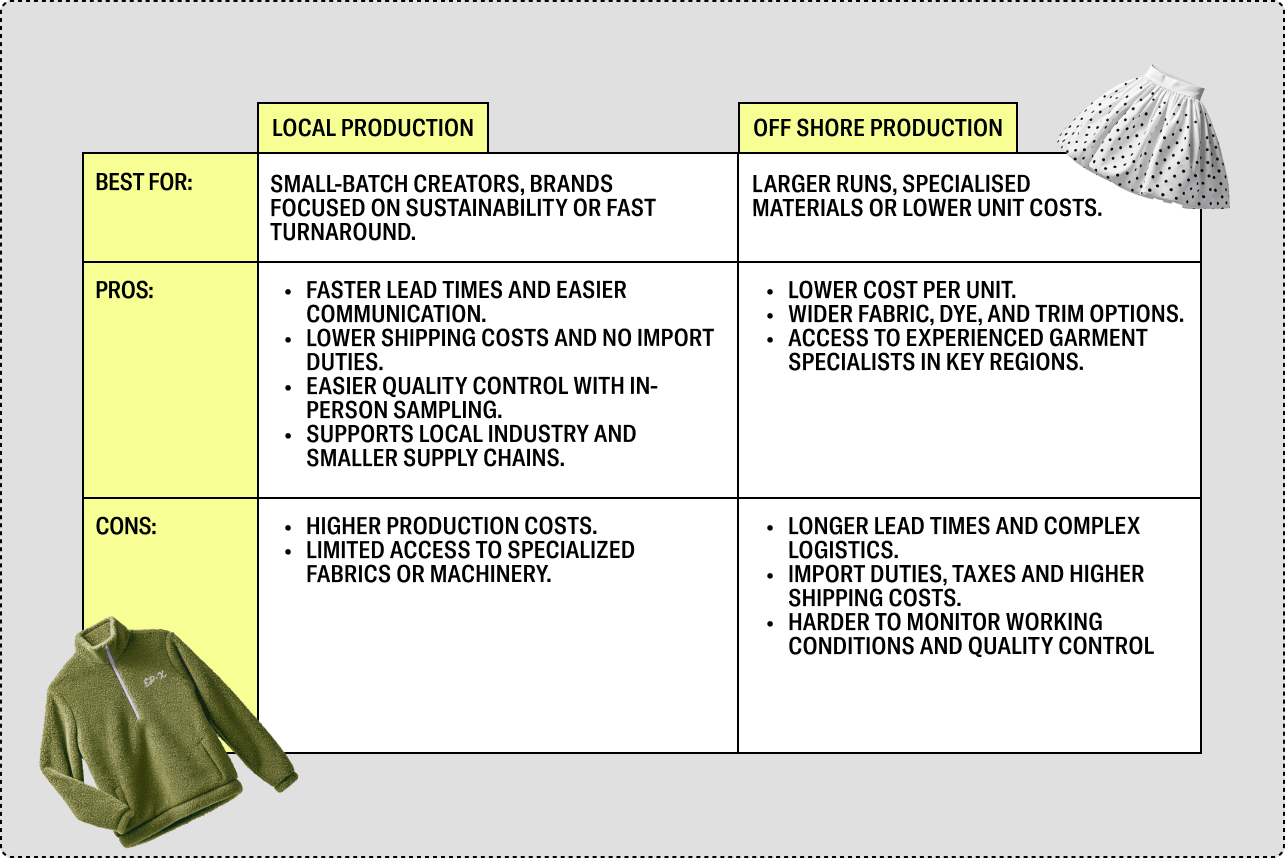

Step 5: Production Paths & Sourcing

Production determines control, cost, and fidelity to your design. The most streamlined process is to design with Fabra then find your manufacturer.

Where to look:

- Vetted directories & trade shows.

- Referrals from adjacent brands/creators.

- Local makers for small batches and fast feedback.

How to vet:

- Share your Fabra tech pack; request a quote with clear inclusions (labels/packaging).

- Order samples early; check stitching, print accuracy, and hand-feel against your spec.

- Confirm MOQs, dye/print capabilities, lead times, and quality checks.

- Check for safe working conditions.

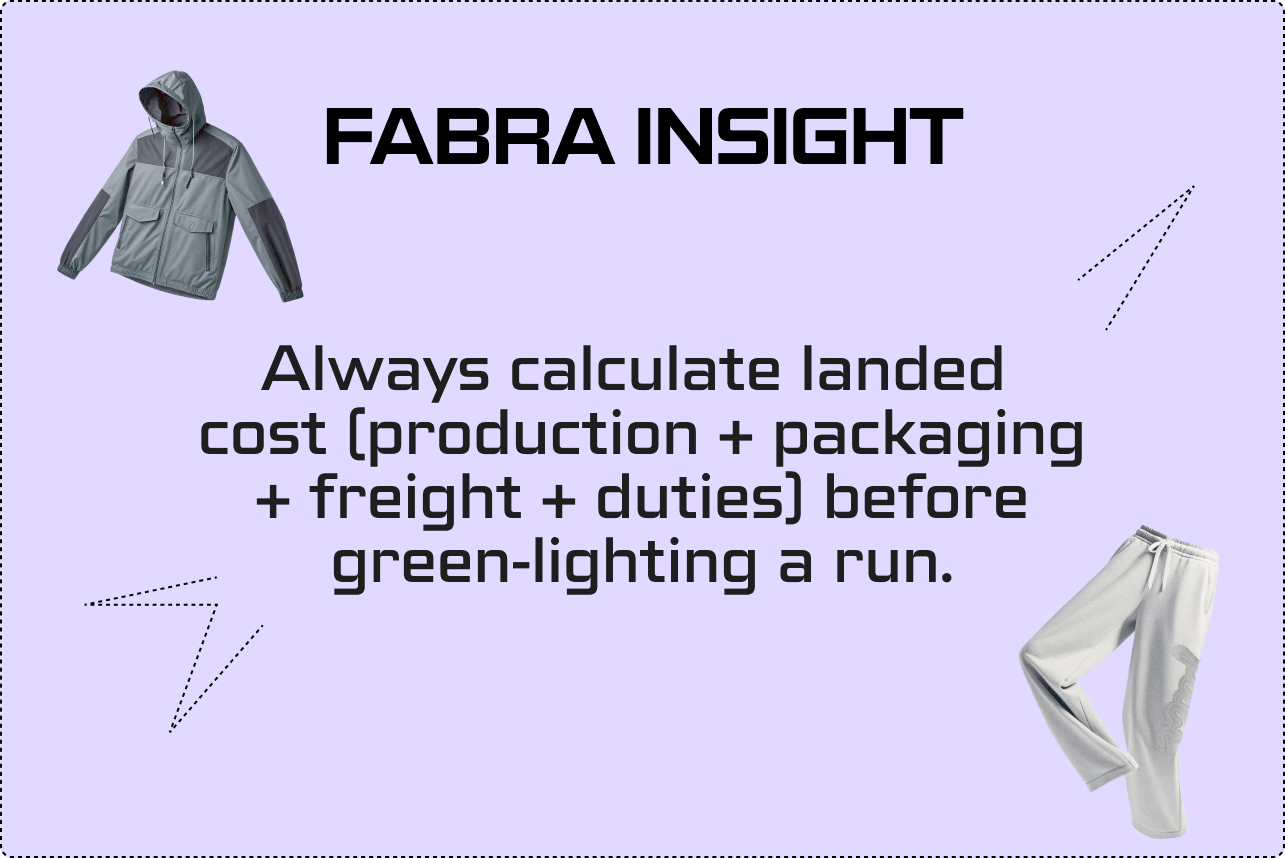

Import duties & distribution

If producing offshore, include duties in landed cost. Global audience? Consider regional 3PL hubs to reduce shipping cost/time.

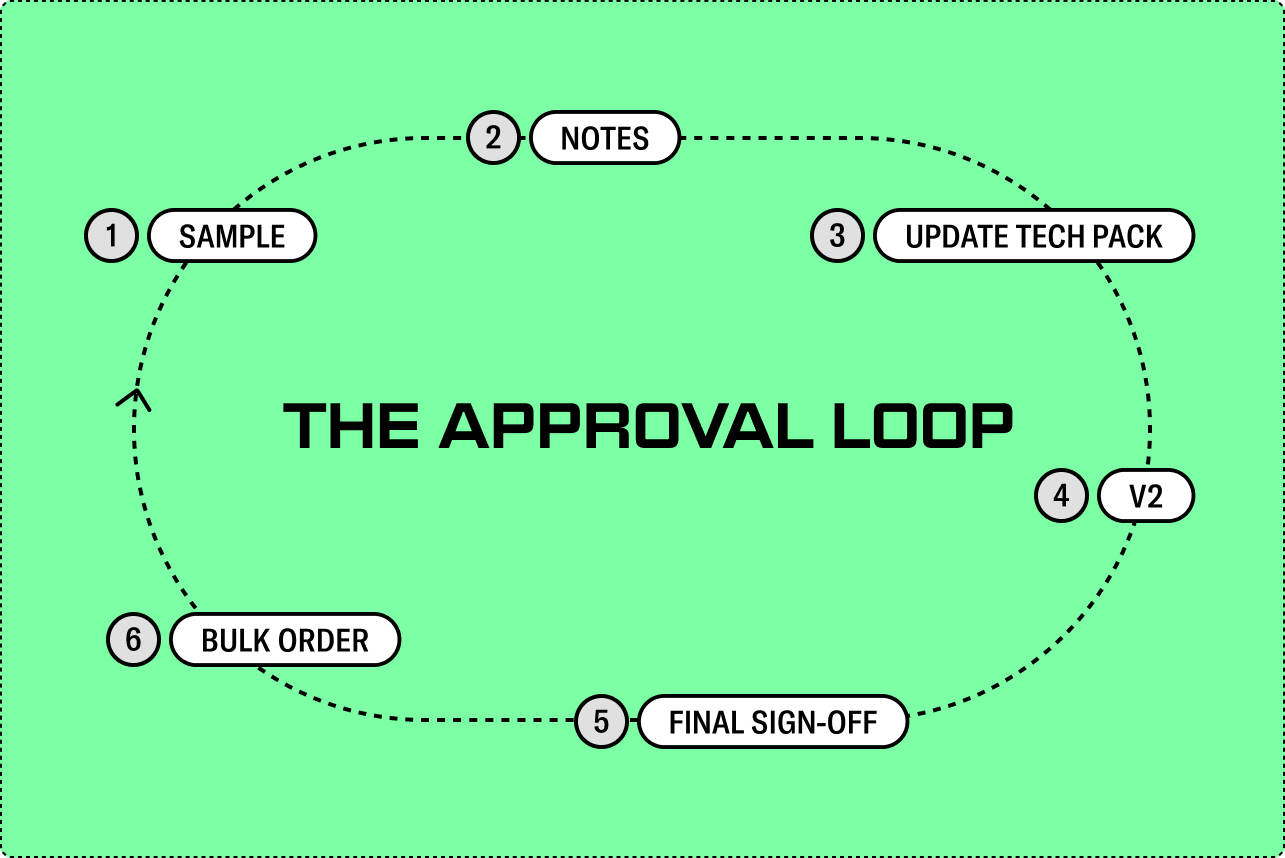

Step 6: Sampling & Approvals

Sampling is where quality gets locked.

Checklist:

- Fit: test on multiple bodies (front/side/back).

- Color: verify under natural light or via sample swatches - dyes shift off-screen.

- Print/embroidery: scale and placement match mockups.

- Fabric feel: weight/drape fit the price you’ll charge.

- Wash test: shrinkage, cracking, bleed.

- Labels: placement, legibility, compliance (content/care/origin).

Step 7: Pricing, Quantities & Drop Model

7.1 Pick your model

- Limited drop: Best for creators and first-time brands testing demand.

- Create scarcity; higher price point possible.

- Ideal for pre-orders or small runs.

- Evergreen range: Best for brands with consistent traffic or retail presence.

- Ongoing availability.

- Consistent restocks.

7.2 How much to order (first drop)

- Total units: 20-100 is common for tests.

- SKU count: 3-6 SKUs (e.g. tee, hoodie, tote).

- Size curve (unisex baseline): S(1) / M(2) / L(2) / XL(1) (refine after your first drop).

- Pre-orders: de-risk inventory; fund production.

- MOQs: remember material MOQs, not just garment MOQs - consolidate fabrics to maximise budget.

Step 8: Packaging, Storage & Fulfillment

Start scrappy, scale when necessary.

- Packaging: Use branded mailers, tissue and a simple thank-you or care card. Keep it sustainable, thoughtful and something customers want to share.

- Storage: Store stock in a clean, dry, shaded space. Label boxes clearly by SKU and size, and track everything with a simple spreadsheet or use an app to track.

- Fulfillment: Start by packing orders yourself to learn what works. When volume grows beyond what you can manage at home, transition to a trusted 3PL.

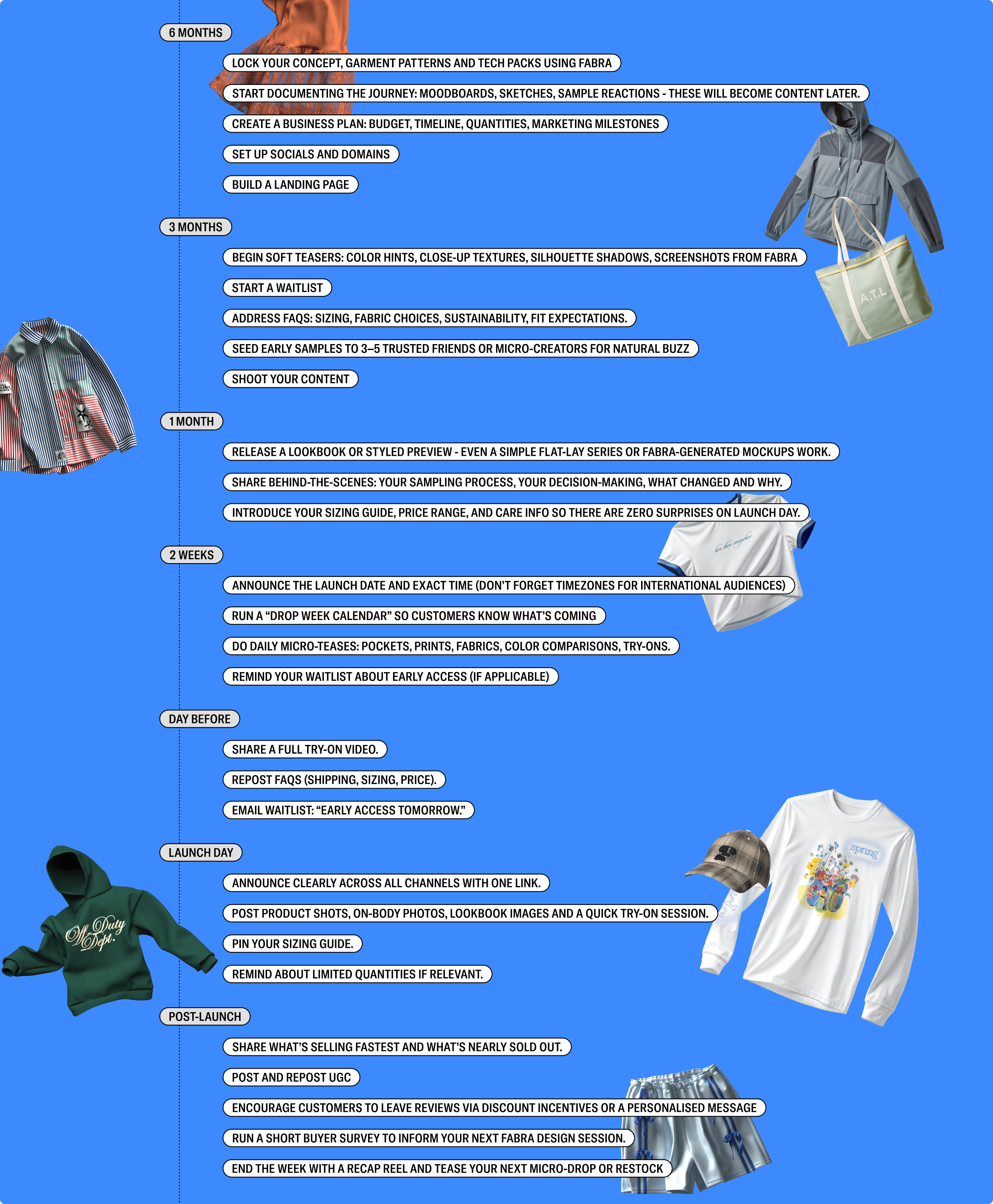

Step 9: Marketing & Launch

The strongest merch drops create anticipation early, educate customers clearly and guide them toward purchase with confidence. Use the below timeline to turn your Fabra designs into a launch that feels intentional, organized and momentum-driven.

Design with Fabra

Fabra helps you bring your design to life. It’s built for founders, designers and creatives who want pro-grade output without getting lost in the production maze.

With Fabra, you can:

- Design in 3D: Explore colors, graphics and placements in real time.

- Export tech packs instantly: Manufacturer-ready, with accurate measurements and artwork placement.

- Collaborate seamlessly: Share links, gather feedback and iterate quickly.

Whether you’re launching your very first drop or refining your tenth, Fabra gives you the speed, flexibility and polish of a full design pipeline - without the learning curve.

Idea in there? Get it in Fabra. Start designing today.